Products

Products

Burn In Board

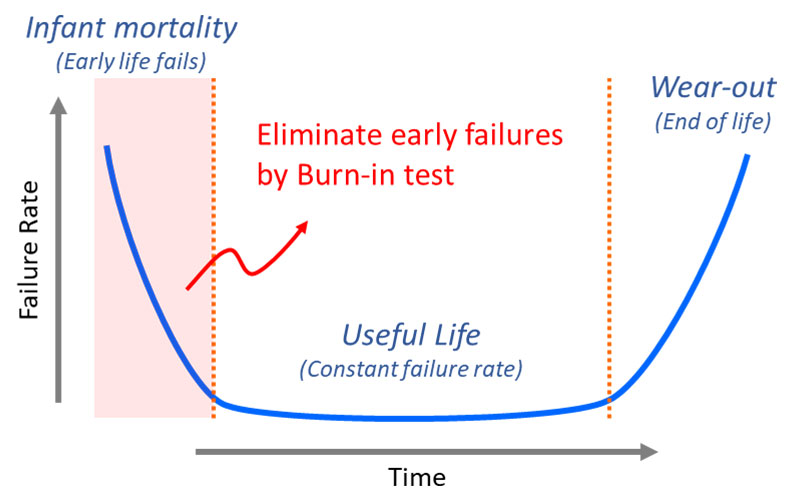

The purpose and principle of Reliability Test

Electronic components shall be subject to a “Burn In” procedure at the embryonic stage of production from the perspective of quality in order to sort out the defects and obtain the Bath-Tube Curve from the statistical data. In other words, there will be a higher defective rate of electronic components at the initial stage and final stage of use. Yet, the defective rate of electronic components will decline and stabilized after using for a certain period of time.

This objective is to sort out the products at the initial stage of production where the production process is not well developed with design defect. The result is potential risk of dysfunction or failure of the products. This test will help to sort out the problem to avoid product failure in the process of use by the customers.

The increasing improvement of packing technology over the years allowed for the placing of several IC in the object for packing that the overall life spans of these IC tend to decline due to the mutual interference of heat conduction among different components. For IC of advanced production process, there will be more transistors located in the same area. The heat generated will be several times of the IC products in the past. Therefore, temperature exerts excessive influence on the life span of the IC which we cannot afford to neglect.

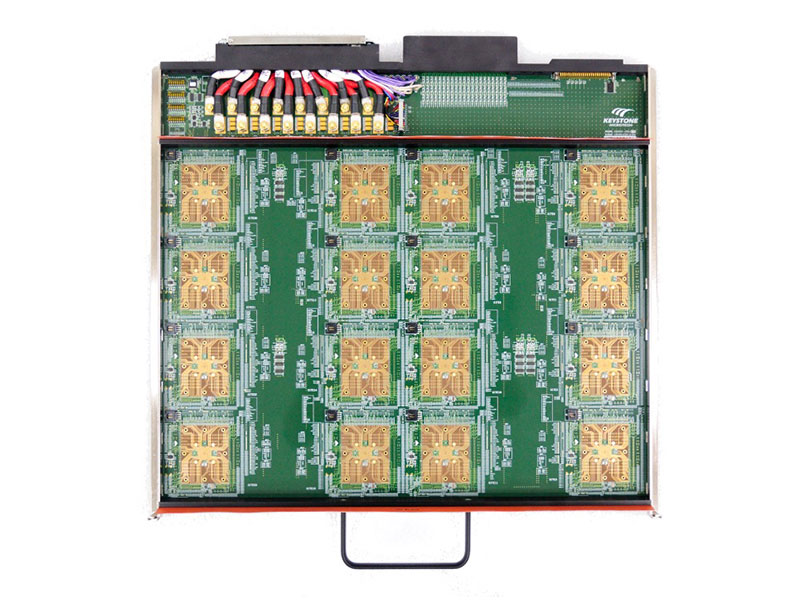

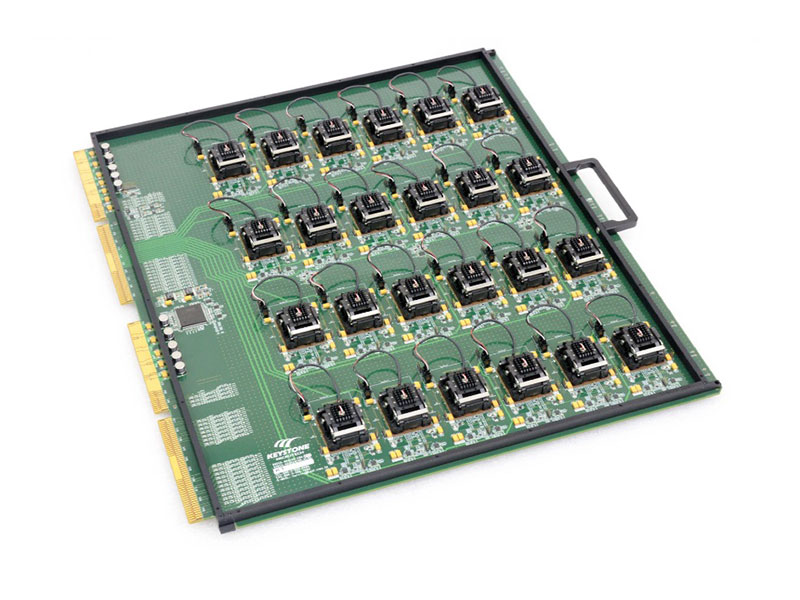

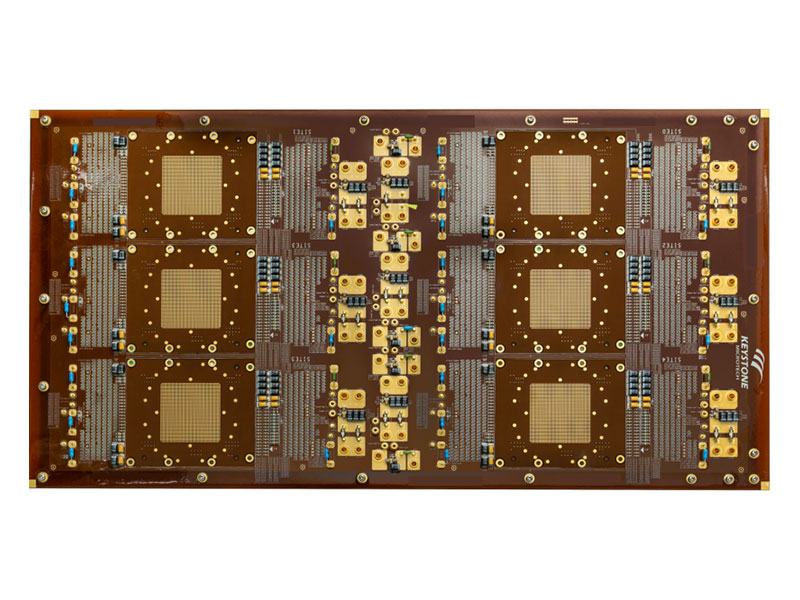

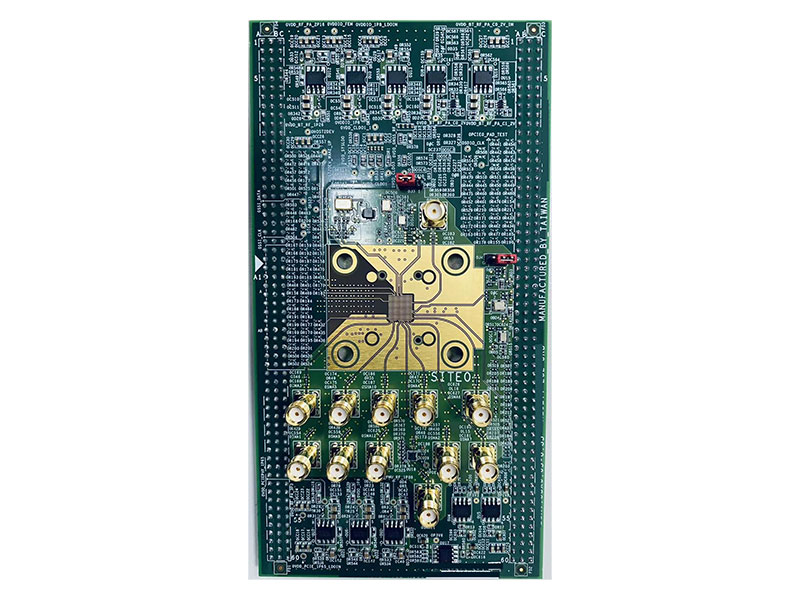

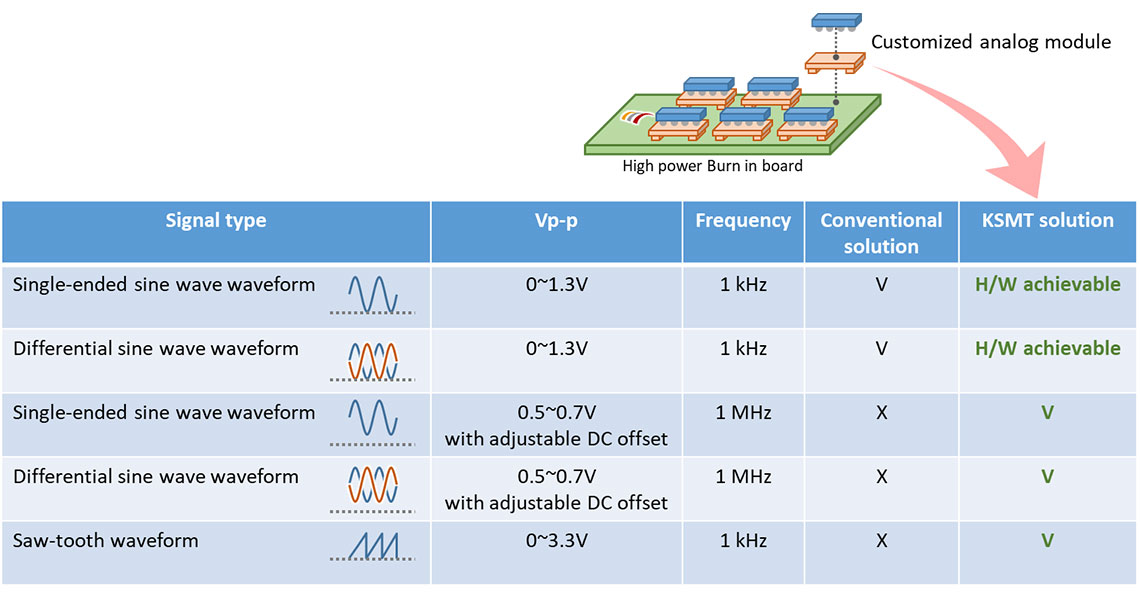

BIB (Burn in Board) is the vehicle of semiconductor IC. Through SOCKET or direct IC mount for combining with BIB, the IC to be tested will be placed in the oven for repeated testing under different temperatures, voltages and signal (HTOL, LTOL, HAST & THB) in order to find out the Bathtub Curve and sort out the defective items at the initial stage and final stage of the product life span. The terminal application of KSMT like AI, HPC, Server, automotive, cell phone, network and base station are well-developed with practical experience, and could meet the needs of the customers.

The design reference of customized Burn in Board and the professional design and production of customized board (products conforming to JEDEC related application rules and regulations)

Burn In Board – HTOL ( High Temperature Operation Life )

In HTOL, products are simulated by a life test in an environment of very high temperature with continued charging (loaded with voltage or current) to test if the functions and features of the products can survive the environmental conditions for assessing the life span of IC products under prolonged running.

Burn In Board - HAST ( High Accelerated Stress Test )

This is the simulation where products are placed under extreme high temperature and humidity. Accelerated water vapor diffuses into the IC through the external protective material and the metallic guide line interface to assess the structure of the IC and its resistance to humidity.